0755-23021978

BA-1000W Waterborne High Strength Epoxy Mortar is a special material used for rapid repair and reinforcement of concrete defects. It has high strength, high adhesion, excellent compressive strength and non-combustible properties. BA-1000W waterborne high strength epoxy mortar is a nonionic self-emulsifying aliphatic amine modified with branched hybrid nanomaterials and bisphenol A diglycidyl ether and multi-chain fatty segment monoglycidyl ether plus grading grade The aggregate is scientifically matched.

0755-23021978

Overview

BA-1000W Waterborne High Strength Epoxy Mortar is a special material used for rapid repair and reinforcement of concrete defects. It has high strength, high adhesion, excellent compressive strength and non-combustible properties.

BA-1000W waterborne high strength epoxy mortar is a nonionic self-emulsifying aliphatic amine modified with branched hybrid nanomaterials and bisphenol A diglycidyl ether and multi-chain fatty segment monoglycidyl ether plus grading grade The aggregate is scientifically matched.

Characteristic

1. Anti-impact, vibration-resistant, good toughness and high compressive strength;

2. construction at room temperature, non-stick appliances, construction is convenient and fast;

3. Non-toxic and non-polluting;

4. Good adhesion to the old concrete base;

5. can be wet base layer bonding, green and environmental protection, the burning level can reach A level.

Advantage

Water-based environmental protection, green products.

Waterproof and moisture resistant, high strength,

Simple operation, quick construction and large-area construction.

Can be used as a leveling layer, low cost, can also be used as a medium coating, can be made 2mm thickness,

The adhesion to the base surface is greatly enhanced, the surface strength is higher, and the ground strength is increased.

Wide range of applications, can be applied on oily coatings, or on waterborne coatings

High material compatibility and can be applied on any material.

Use

1. Repair and reinforcement of concrete structure defects, honeycombs, and pockmarks;

2. Repair and protection of the overflow surface of hydraulic structures after impact abrasion, cavitation resistance and freeze-thaw resistance;

3. Protection and repair of corrosion resistance of acid or alkali salts of concrete or metal components such as chemical plants and docks;

4. Repair and reinforcement of major stress components such as roads and bridges;

5. Anti-wear protection and repair of engineering sites such as airport runways and workshops;

6. The surface defects of the concrete pipe and the quick closing bond of the joint;

7. Filling repair of prefabricated component assembly gaps.

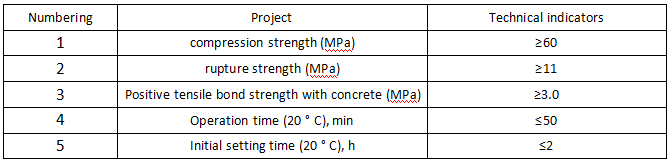

Performance

Construction instructions

①When 1BA-1000W is used as interface agent:

The group A and the group B were mixed in proportion (3:1), and after emulsification for 3-5 minutes, 15% of the total amount of water (i.e., 20% of the component A) was mixed and mixed, and uniformly sprayed on the ground.

②Construction of waterborne epoxy strong mortar

Firstly mix the BA-1000W in proportion, and wait for 3-5 minutes for complete emulsification. (Emulsification standard is the same as above) Add cement and quartz sand in sequence to mix and mix uniformly. Finally, add water in proportion to stir evenly to form water-based rigid mortar.

Inspection standard: Use a transparent cup to take a small amount of the stirred mixture. If there is oil on the bottom of the cup, it means that the emulsion is not emulsified. Continue to stir; if there is no oil, it means the emulsification is completed.

Construction method

1. Grassroots requirements and handling:

Grinding removes the loose layer on the surface of the concrete base layer, revealing a solid base surface, thoroughly sweeping the surface of the floating ash, the base layer is required to be firm and dry; no through-wide cracks.

2. Material preparation:

a. emulsion ratio: BA-1000W component A: BA-1000W component B = 3:1 (weight ratio);

b. BA-1000W waterborne high strength epoxy mortar ratio: BA-1000W A component: BA-1000W component B: BA-1000W aggregate: water = 3:1:24:4 or so (weight ratio), according to the temperature , the amount of water used for façade or plane construction;

c. A and B components take-up containers are used separately, each batch should not be too much, with the use, with up to 40 minutes.

3. Construction:

a. Brushing emulsion: Stir the prepared BA-1000W emulsion evenly, adopt roller coating or brushing method, apply uniform on the treated base layer, and make the thickness uniform, ensuring complete coating of the base layer. The next process can be carried out at intervals of 2 to 4 hours;

b. Scrape the mortar: After the emulsion is solidified, immediately fill the prepared BA-1000W mortar with a flat knife;

c. Maintenance: Generally no maintenance is needed, but when the coating is thicker, it should be cured for 2 days.

Reference dosage: about 2kg/m2 (based on the thickness of the bonding layer 1mm)

Packing: BA-1000W Group A 15 kg / barrel, BA-1000W Group B 5 kg / barrel, BA-1000W aggregate 25 kg / bag

Tool cleaning: water.

Construction conditions: It is recommended to use this product above 10 °C. In order to avoid condensation of water vapor, the construction base surface is required to be dry and clean, the moisture content of the base surface is less than 4%, and the relative humidity of the air is less than 85%. Good ventilation should be maintained during construction and drying in confined spaces.

First paint: first apply epoxy base oil and medium coat.

Add paint: no.

Precautions

a. When using in the field, it is strictly forbidden to mix any admixture and external admixture in BA-1000W. Do not mix with materials produced by other manufacturers to ensure the quality of the project.

b. Wash the tool with water immediately after use. The cured material can only be removed by mechanical means.

Storage: sealed and stored in a cool, ventilated place, protected from moisture, sun, and frost.

Warranty period: Unopened for 12 months.

Safety

Use this product with care. Swallowing is harmful or fatal. If swallowed, seek medical attention immediately. Skin, eyes should not touch this product. Always take precautions, fire and explosion protection. Residues should be disposed of in accordance with the safety regulations of the relevant national or local government.

Important statement

Caitian Company guarantees the quality of its products. The advice and information provided here is from our independent laboratory and is accurate under controlled conditions, but since we are unable to perform direct and continuous control during the use of the product, whether or not it is provided Recommendations, recommendations, programs and materials, Caitian does not assume any direct or indirect liability arising from the use of the product.

The above information comes from Shenzhen Caitian Chemical Co., Ltd., please indicate the source.