0755-23021978

Overview of a room temperature curing three-component epoxy resin anticorrosive paint use This product is suitable for a variety of buildings, metal parts, steel brackets, steel bridges, metal storage tanks and other large steel structure anticorrosive anti-corrosive coating painting characteristics excellent corrosion resistance; excellent resistance to oil, solvents, water and salt spray resistance; good surface adhesion of the substrate.

0755-23021978

Overview

A room temperature curing three-component epoxy resin anticorrosive paint.

Usage

This product is suitable for anti-corrosion and anti-rust coating of metal parts of various buildings, steel supports, steel bridges, metal storage tanks and other large steel structures.

Characteristic

Excellent anti-corrosion properties; excellent oil resistance, solvent resistance, water resistance and salt spray resistance; good adhesion to the substrate surface.

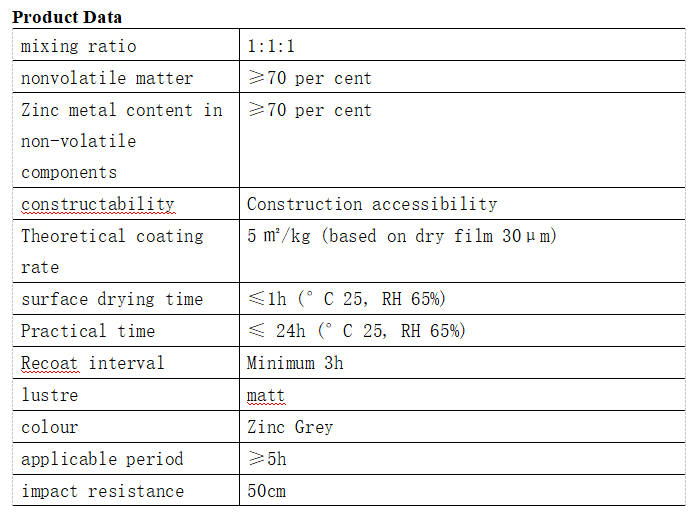

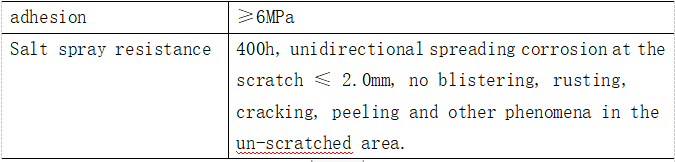

Product Parameters

BA-85#

Construction instructions

Use cleaner to remove all the oil and dirt on the surface, sandblast to Sa2.5 or power tool to remove rust up to St3, roughness 40-70μm, and keep the surface clean and dry; can be sprayed, brushed or rolled; the actual dosage is related to the construction method and the roughness of the base surface.

Construction conditions

Ambient temperature ≥10℃, relative humidity ≤80%, and the surface temperature of the workpiece is more than 3℃ above the dew point temperature; the construction can be carried out when the temperature is 5-10℃, but the curing speed will be very slow.

Precautions

Keep the air circulation in the construction environment; the temperature is lower than 5℃, rainy days or excessively humid weather prohibit construction; excessive dilution will increase the risk of painting, and is likely to produce the paint film is not rich enough, the rust prevention ability to decline and other problems, and ultimately reduce the comprehensive performance of the coating film; a film can not be too thick, it is recommended that the dry film thickness of a single coat does not exceed 50μm!

Special Reminder

Zinc-rich primer film in the air exposure for a long time, the surface will appear zinc salts, especially in the industrial atmosphere or marine climate will quickly produce zinc salts, reduce the anti-corrosion properties, so the primer can not be coated before the latter paint exposure for a long time.

Safety measures

This product must be used by professionals in industrial places, please refer to this instruction manual and the health and safety manual when using, if the customer fails to understand the health and safety knowledge about the product carefully before using this product, please contact our company. Effective measures should be taken to prevent skin and eye contact with the paint before construction (e.g. use of coveralls, gloves, goggles, protective masks, etc.), if the product accidentally comes into contact with the skin, it should be washed thoroughly with warm water and soap, and if the eyes are contaminated flush them with water for at least 10 minutes and seek immediate medical attention. Swallowing is harmful or fatal, if swallowed should immediately seek medical attention. Always take precautions against fire and explosion. Disposal of residues and used paint buckets should be in accordance with the safety regulations of the country or local government concerned.

Important Disclaimer

We guarantee the quality of our products. The advice and information provided herein has been obtained from our independent laboratories and is accurate under controlled conditions. However, as no direct and continuous control can be exercised during the use of the products, the company disclaims any direct or indirect liability arising out of the use of the products, whether or not the advice, recommendations, programs, and information provided are used.