0755-23021978

2024-05-31 11:24:36 0

BUILDING ROOF INSULATION COATING CONSTRUCTION SCHEME

CONSTRUCTION TECHNOLOGY DESCRIPTION

---------

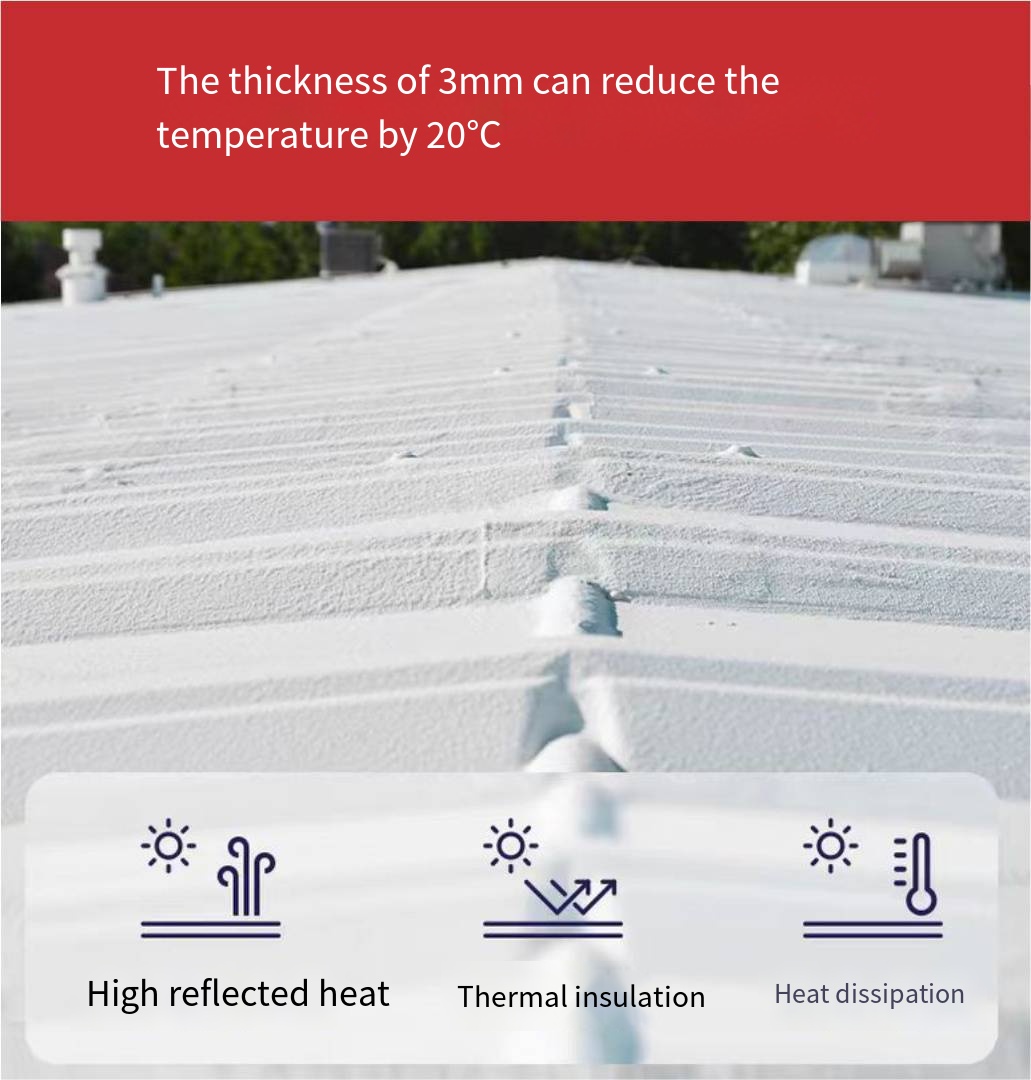

01 PRODUCT INTRODUCTION

Caitian BA-920 water-based nano roof reflective heat insulation coating is made of hollow ceramic microbeads, reinforced composite materials, heat reflective substances, water-based nano binders and excellent additives, coated on the surface of the substrate to provide a heat-reflective heat insulation coating, using the new third generation of high reflection heat insulation and cooling technology, is a nano-composite resin as the base material of high reflection, sun protection, sun protection. Heat reflection, heat insulation, cooling, radiative heat, cooling, constant temperature, waterproof, weather resistance, protection in one of the multi-functional reflective sunscreen coating, substrate cooling 20-30 ° C, internal cooling 8-12 ° C, protect the substrate to extend life.

02 PRODUCT FEATURES AND SCOPE OF USE

03 CONSTRUCTION PROCESS DESCRIPTION

STEP1 : BASE SURFACE TREATMENT

Carefully check the metal interior ceiling before construction to ensure that the metal interior ceiling is firm, no rust, no water, dust, oil, dirt and other loose objects. Failure to meet the above conditions shall be dealt with as follows:

1/ high-pressure air gun to clean up all impurities and dust; Sand blasting to minimum Sa2 level, power tool cleaning to St3 level. Base surface requirements: smooth, firm, Yin and Yang Angle smooth, straight. No dust, honeycomb surface, rust, steel bar head, sand, loose, crack, sand hole. After the acceptance of the base surface, the next step of construction can be carried out.

2/ replace the rusty firmware, add the firmware in the appropriate position;

3/ local rusty places, use sandpaper to clean the rusty area until the metal primary color;

4/remove water, dust, oil, rust, dirt and other loose objects; Protect finished products and semi-finished products. Including doors, Windows, door frames and glass; Outdoor downspouts; Other exterior wall decorations, etc.

STEP 2 : THERMAL INSULATION COATING APPLICATION

1, you can add 10-30% clean water, make sure to mix evenly before spraying.

2, it is recommended to use airless spraying, spraying one is not more than 2mm, spraying the second after the surface finger dry, so until the spray to the required film thickness. Scraping can also be used, a scraping should not exceed 2mm, after the surface of the finger dry, scraping the second.

3, taking 3mm thickness as an example: it is necessary to spray two times, the first time 1㎜, the second time 2㎜, the loss spraying amount is about: 1㎜ thickness to 1.1 kg/square meter.

STEP 3 :MATTERS NEEDING ATTENTION

Construction conditions: The construction surface must be clean and the temperature above the dew point to avoid condensation. Use above 10℃ to ensure volatilization and drying of construction water. Paint storage and construction state should be above 10℃ is appropriate, if the relative humidity is greater than 85%, the construction space should be maintained good ventilation to promote the volatilization and drying of water. If the construction is directly on the surface containing heat, the surface temperature should not exceed 80 ° C to avoid foaming. of poor ventilation environment, carefully handle the old paint drum to avoid polluting the environment.

Film thickness: Adjust the film thickness according to the purpose and area of use, but it will affect the coating rate, the amount of thinner, the drying time and the recoating interval. Usually, the thickness of a single channel is 500 microns, and a second channel can be sprayed after the surface is dry to avoid bubbles and other defects caused by excessive spray thickness.